Explained: How ethanol blending will help India save on fuel bill

Ethanol blending is used worldwide to bolster energy security while also providing a cleaner fuel Indian government's ethanol-blending efforts have already yielded fuel import cost savings of Rs 41,000 crore over the last eight years Reduced fuel efficiency and water build-up concerns are some of the disadvantages of ethanol blending

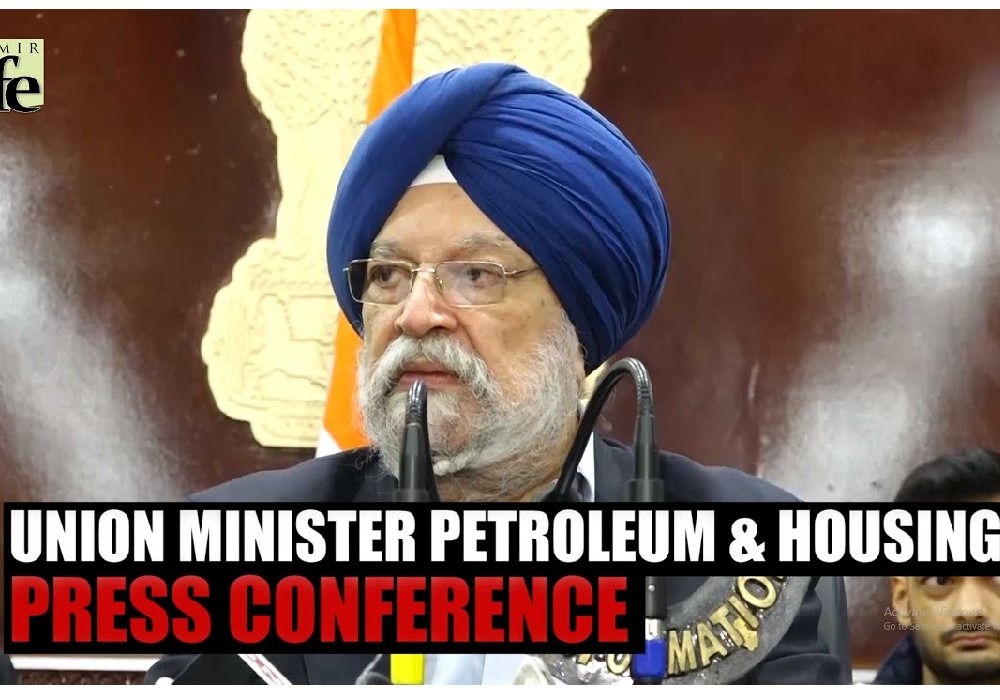

On Monday, June 6, India's Union Minister for Petroleum and Natural Gas, Hardeep Singh Puri stated that some petrol pumps in the country may be able to start selling 20 per cent ethanol-blended petrol ahead of the 2025 deadline previously given by the government. Puri made the remarks during the course of the 'Leaders of Climate Change Management' programme where he asserted that the government's plans have "full emphasis on green sustainability."

The minister's remarks follow an announcement by PM Narendra Modi last weekend that the country had achieved its goal of 10 per cent ethanol-blended petrol five months ahead of schedule. India's move to set a more ambitious goal for the blending of petrol and ethanol comes at a time when the world is facing a major fuel crisis as well as the ever-advancing threat of climate change disaster. But what exactly is ethanol-blended petrol and why is the government pushing for increased adoption for the same? Read on to find out.

What is ethanol-blended petrol? Ethanol is a fuel made from various plant materials collectively referred to as 'biomass'. The biofuel is procured from the fermentation and distillation of sugarcane and damaged food grains such as rice. The raw materials for the production of ethanol can vary from country to country. While the US produces ethanol using corn, Brazil makes use of sugarcane. Regardless of whether ethanol is produced from sugar or starch-based feed, the end product has the same chemical formula.

Ethanol is a colourless liquid with a higher octane number than gasoline, allowing it to increase the petrol octane number when blended. Ethanol is also considered a renewable energy source, given its raw materials and process for making it. Ethanol and ethanol-blended fuel are used worldwide with agricultural powerhouses like the US and Brazil particularly leading in the use of such renewable energy sources.

In the US for instance, around 98 per cent of the gasoline contains ethanol, typically E10 (10 per cent ethanol blended with 90 per cent of fossil fuel, in this case, gasoline). Ethanol has different types of fuel blends with varying ratios. E5 (5 per cent ethanol), E15 (15 per cent) and E20 (20 per cent) are some other blends that are used worldwide. A less common blend is E85, also known as flex-fuel, which is actually petrol-blended ethanol rather than the other way around as it contains up to 85 per cent ethanol with the remainder being a fossil fuel like petrol or gasoline. It should be noted that certain types of engines can also freely use pure ethanol or E100 as fuel though there are various challenges associated with its use. Why is ethanol-blending used? There are a number of reasons why countries like India and the USA are making increased use of ethanol blends. The primary reason is generally energy security. India imports some 85 per cent of its crude oil which makes the nation increasingly vulnerable to global fuel shortages and price hikes. In this case, blending ethanol with petrol will not only reduce the fuel import bill for India but also contribute to greater self-reliance as the nation expands its own ethanol production capabilities. Additionally, ethanol usage also comes with reduced greenhouse gas emissions with the US Department of Energy stating that corn-based ethanol, for instance, results in 40 per cent reduced emissions as compared to the extraction and use of fossil fuels like diesel, gasoline and petrol. There are other benefits still, particularly for the agricultural sector given the method and raw material used for ethanol production. In the US for instance, ethanol production in 2020 accounted for 62,000 jobs and added $35 billion to the GDP. In India, according to figures put out by the government, the achievement of 10 per cent ethanol-petrol blending comes with a reduction of carbon emissions by 27 tonnes while also saving the country Rs 41,000 crore in oil import expenses over the last eight years. Additionally, the achievement has also reportedly boosted the income of farmers by Rs 40,000 crore in the same time period. What are the disadvantages? For all its advantages, ethanol-blending does come with a few disadvantages as well. One of the primary problems is that ethanol is less energy-efficient as compared to something like petrol. A vehicle running on pure ethanol will have a fuel economy that is 30 to 35 per cent less than that of a vehicle using pure petrol. When it comes to blends, something like E20 would give a vehicle a fuel economy five to seven per cent less than that of a vehicle running on unadulterated petrol. This can, naturally, lead to increased costs for consumers who will have to fill up their tanks more often when using ethanol blends. It is for this reason that the expert committee that produced the Roadmap for Ethanol Blending in India 2020-25 recommended that the government should subsidise the price of ethanol and provide tax breaks to compensate for the reduction in calorific value and boost acceptance of blended fuels. Then there is the problem of water building up in tanks that hold pure ethanol or ethanol blends. Ethanol strongly attracts water and, over time, a tank containing pure ethanol or a blend will have an accumulation of water. Since water is heavier than fuel, it sinks to the bottom of the tank. Water build-up in ethanol tanks can lead to a number of problems, one of them being phase separation. Phase separation happens when there is enough water in a tank to start combining with the ethanol in the fuel. This leads to the formation of two distinct layers in the tanks. The first one on top is that of pure fossil fuel like petrol with a heavier layer of water mixed with ethanol underneath it. To date, there is no quick-fix, winning solution to the problem of water building up in ethanol tanks with companies expending considerable expertise and resources in trying to prevent the problem. Finally, it should also be noted that ethanol and ethanol blends cannot simply be used in every single vehicle without consequence. While an E5 blend may be useable by most engines without any concerns for wear and tear, E10 can cause damage to plastic, rubber and aluminium components of the engine unless a vehicle manufacturer specifically builds an engine to handle this higher concentration. The use of E20 or the so-called 'flex-fuel' E85 requires manufacturers to make further changes to their engines and vehicle components. That said, it is possible to run an older vehicle with ethanol blends though this will naturally come with reduced fuel efficiency and an increase in vehicle maintenance and servicing.

Synopsis Union Minister Hardeep Singh Puri stated India's commitment to an inclusive global energy future through open collaboration, highlighting the India-Middle ..

देश में एक करोड़ यात्री प्रतिदिन कर रहे हैं मेट्रो की सवारी: पुरी ..

Union Minister for Petroleum and Natural Gas and Housing and Urban Affairs, Hardeep Singh Puri addressing a press conference in ..

Joint Press Conference by Shri Hardeep Singh Puri & Dr Sudhanshu Trivedi at BJP HQ| LIVE | ISM MEDIA ..

(3).jpg)

"I wish a speedy recovery to former Prime Minister Dr Manmohan Singh Ji. God grant him good health," Puri wrote. ..